the melotti family

OUR STORY began...

Starting from two hectares of rice paddies but there is still a long road ahead!

Over the 1980s, the economic income of the small farms was becoming less and less sufficient due to the low value of cereals and Giuseppe Melotti had to deal with the problem of guaranteeing a future for his children. In the spring of 1986, Giuseppe Melotti sowed one hectare and a half of rice paddies by hand. From the very beginning, he began to cultivate and sell the best Italian rice varieties, such as Vialone Nano Veronese Rice and Carnaroli Rice, on his own behalf. That forward-looking choice anticipated the today widespread concept of the Short Supply Chain.

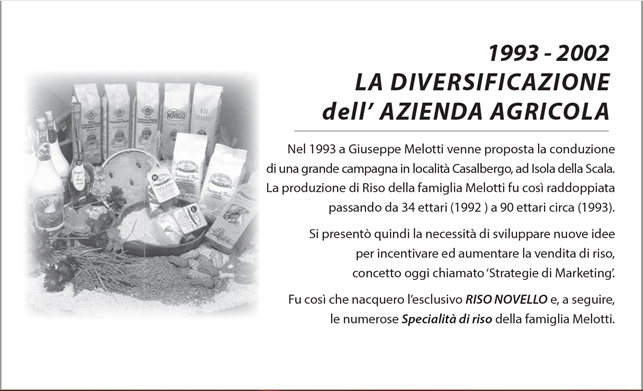

Today the Melotti Farm is managed with passion by the founder Giuseppe and his wife Rosa, known as “Rosetta”, along with their sons Luca and Gianmaria and their daughter Francesca. Thanks to the creativity of Melotti family and following the delicious Mamma Rosetta’s recipes, Rice-based specialities and Melotti Rice Flour were, for the first time, produced. Until today, there are more than 60 Rice-based products.

Telling its story and its work becomes an important activity for the farm. Therefore, Melotti family decided to start its own Educational Farm. A real 360° journey in the world of rice, organised for classes and groups. Today, a lot of groups and classes visit the Melotti Educational Farm.

Thanks to Mamma Rosetta’s culinary experience, in 2002 Risotteria Melotti was opened in the heart of Isola della Scala and in 2013 another dream came true for the family: to inaugurate a Risotteria Melotti in New York. These traditional and unique restaurants offer a completely rice-based cuisine and a wide selection of risotti and wines from Verona and Veneto. Four years after, Riso Melotti succeeded in opening in the Italian capital: in fact, in February 2017, Risotteria Melotti was inaugurated in Rome, in the historical centre, near Piazza Navona. Starting from July 2021 Risotteria Melotti is located in Florence, a few feet away from the Cathedral of Santa Maria del Fiore and from April 2024 in the very lively city of Milan, not so far from Navigli district.

Riso Melotti can also be found in small and prestigious delicatessens that provide refined and high-quality products, as well as it is used by chefs in renowned restaurants in Italy and abroad.

100% Melotti Rice

Short Food Supply Chain to guarantee quality!

The decision to produce and process only its own rice, following very high-quality criteria, was a courageous choice for Melotti family, which has been pursued and strengthened over the years.

The care and the attention paid to the choice and the cultivation of the best lands are the same paid to the rice processing. Indeed, it does not undergo any chemical intervention or any handling, keeping, in this way, the rice final properties intact and unchanged up to the table of food lovers.

Our daily commitment is to pay great attention to every step of our work. The Traceability of the product and the guarantee of its origin are essential factors for Melotti family.

” THE BEST EARS OF RICE GROW

ON CAREFULLY TENDED GROUND”

The Melotti family has always taken care of the land on which it sows its rice. It is from the preparation of this land, ploughed, levelled and fertilised with care that the good cultivation of Vialone Nano Veronese and Carnaroli Rice begins.

An indispensable job that is repeated every year…

” THE BEST RICE PANICLES OF RICE GROW

ON CAREFULLY WORKED FIELDS”

Melotti family has always been taking care of the fields on which the rice is sown. The preparation of the land, which is ploughed, levelled and fertilised, is the base for beginning a good cultivation of Vialone Nano Rice and Carnaroli Rice.

A necessary job that is repeated every year…

Ancient methods handed down over the years...

Delicate craftsmanship

Particular attention is also paid to the processing of our rice, a system which has adapted to new technologies over the years but which maintains the artisan methods used since ancient times.

The grain is cleaned of its outer husk, ‘the Chaff’, by passing through rubber rollers that delicately remove the outer layers and is further whitened using mechanical processes that do not alter the characteristics of the product. The different stages of processing make it possible to obtain rice rich in fibre, in whole grain processing and more refined rice such as semi-processed or milled.

The colour, thanks to this tenuous processing, will always remain slightly ivory and not white like the colour of classic industrial rice.

We process and package our rice a little at a time, so that it arrives as freshly husked as possible – this is the name given to the processing of rice – on your table.

Sustainable energy and Recyclable packaging

100% sustainable production chain

Since 2021, the Melotti Giuseppe Agricultural Company has been consuming agricultural energy at km 0, making its production chain 100% sustainable. By joining the 0 km agricultural energy project and consuming the same 100% renewable, traceable and certified EKOenergy energy produced by the Coldiretti Vento Members, it contributes every year to avoiding the emission of more than 56 tons of CO2 into the atmosphere, actively helping the environment and bringing many other people closer to natural energy consumption by example.

118: THE EQUIVALENT BARRELS OF OIL AVOIDED EVERY YEAR

Particular attention is paid to product preservation when choosing the packaging. The rice preserves perfectly thanks to the presence of a filter that prevents moisture from coming into contact with it. Instead of vacuum packaging, which takes away the freshness and aroma of the product, we prefer artisanal packaging with a modified atmosphere (map).

MELOTTI FAMILY RICE PACKAGING is also RECYCLABLE!

For us, it is of utmost importance to use sustainable packaging without compromising the protection of our product. We choose our materials carefully so that they can be recycled without harming the planet.

Ancient methods handed down over the years...

A delicate artisanal processing

A very particular attention is also paid to the processing of our rice. A system, which has been adapting to new technologies over the years, but at the same time, preserves its ancient and artisan methods used a long time ago.

The external rice hull, the “Husk”, is removed from the grain by passing it through some rubber rollers that carefully eliminate the outer layers. Then it is further whitened using mechanical processes that do not alter the product characteristics. Thanks to these different processing steps, the rice maintains its high quantity of fibres, in particular for the wholegrain and more refined processing such as semi-refined or refined rice.

The grain colour, by this delicate processing, always remains slightly ivory and it does not become white like the one of the classic industrial rice.

We process and package our rice little by little, so that it arrives on your table as freshly husked as possible – husking is the name given to this particular rice processing.

Sustainable energy and Recyclable packaging

100% sustainable production chain

118: THE NUMBER OF OIL BARRELS AVOIDED EVERY YEAR

Particular attention is paid to product preservation when choosing the packaging. The rice keeps its characteristics intact thanks to the presence of a particular filter that prevents moisture from coming into contact with it. Instead of vacuum packaging, which takes away the freshness and aroma of the product, we prefer an artisanal packaging with a modified atmosphere (map).

THE RICE PACKAGING OF MELOTTI FAMILY is also RECYCLABLE!

It is of utmost importance for us to use sustainable packaging without compromising the protection of our product. We choose our materials carefully so that they can be recycled without harming the planet.